絞り込み

Pumps for Specific Applications

Chemical Models

-

TMEX models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Two-stage planetary gear reduction enables long-term continuous operation.

●Special rubber for high pressure resistance and Teflon lining are standard specifications, so it has excellent chemical resistance, and the horizontal repetitive motion of the rod enables the diaphragm to last forever.

●Strengthen the internal mechanism. Stepless adjustment is possible regardless of whether it is running or stopped.

●It is designed so that the intake and discharge valves are completely closed, the discharge rate is stable, and the performance curve is almost straight. -

TMTX models

- Pumps for Specific ApplicationsChemical Models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Since the entire pump is covered with plastic, there is almost no rust and the appearance is not spoiled.

●Long-term continuous operation is possible due to planetary gear two-stage reduction.

●Aluminum material is used in combination to reduce weight.

● Quality has been improved by improving the ratchet mechanism. -

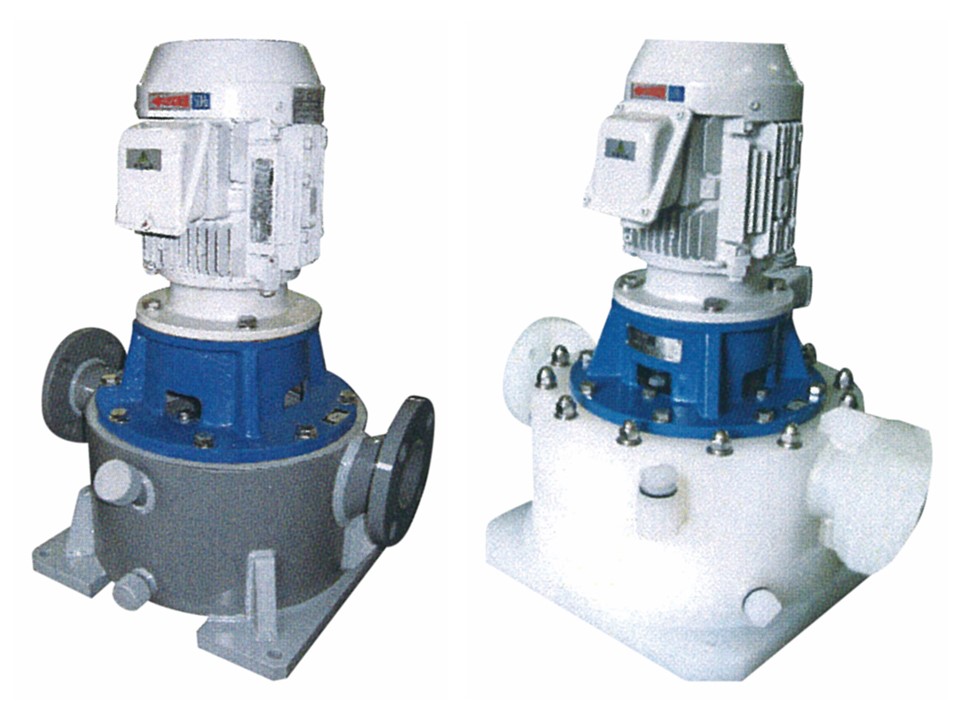

TMOK-S models

- Pumps for Specific ApplicationsChemical Models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●The adoption of CSS (centrifugal shaft seal device) ensures that the seal is non-contact and non-sliding during operation.

There is no wear of seals due to slurry or heat generation due to dry operation.

●It is also possible to manufacture PTFE or UPE depending on the liquid used. -

TMOK-V models

- Pumps for Specific ApplicationsChemical Models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Dry operation is OK due to the non-seal structure.

●Few consumable parts. -

TN models

- Pumps for Specific ApplicationsChemical Models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Magnetic pump for a wide range of chemicals.

●Faithful to the basics, highly reliable and long-life design.

● Abundant series configuration from 6W to 250W. -

TM models

- Pumps for Specific ApplicationsChemical Models

- Pumps for Specific ApplicationsChemical Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●As a medium-capacity chemical magnet pump, materials and structures for a wide range of chemical liquids are available.

●There is no liquid leakage due to the magnet drive structure.

●It supports a wide range of chemicals by selecting the wetted part material.

●Casting (FCD) models with an exterior cover are ideal for high temperature and high pressure applications.

● All standard motors are totally enclosed fan-cooled outdoor type.

●It has a long service life by adopting a structure that is resistant to idling.

FAQs

Provides help information on how to use each product and when you have problems.