絞り込み

-

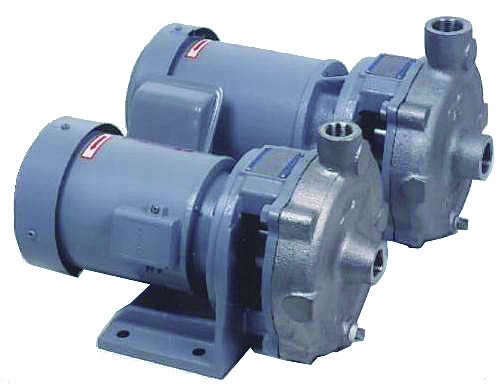

TFSD (2P) mechanical seal models

- On-Land Pumps (Stainless Steel)Close-Coupled/Non-Self-Priming Models

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

● Excellent durability due to the adoption of stainless steel casting.

● A highly reliable mechanical seal (SiC) is used for the shaft seal.

●The impeller adopts a durable semi-open type, and can pass some solid objects.

●Simple and compact integrated motor shaft structure eliminates the need for centering.

●Because of the center top structure, the discharge direction can be changed freely regardless of the mounting direction.

● Quiet driving sound. -

CS-N models (non-automatic)

- Submersible PumpsPlastic/stainless steel models

for fishing

for fishing for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

● High-grade stainless steel SUS316 and SCS14 are used for all wetted parts. Resistant to acids, alkalis and salts.

● A double mechanical seal with excellent corrosion resistance and durability is used for the shaft seal.

●Equipped with an automatic burnout prevention device in the motor. (7.5kW or less) -

TCVS models (non-automatic)

- Submersible PumpsCast Iron Models

for civil engineering

for civil engineering for industrial equipment

for industrial equipment for kitchen wastewater

for kitchen wastewater for pit gray water

for pit gray water for septic tank

for septic tank

●The newly designed high-performance whirlpool impeller prevents clogging and winding even in sewage containing fibrous contaminants.

● Low-wear type that prevents foreign matter from directly passing through the impeller.

●Built-in automatic return type motor protection device (auto cut).

●The shaft seal uses a double mechanical seal and an oil seal. (1.5 kW or more when combined with an oil seal)

●SiC with excellent wear resistance is used for the sliding part of the mechanical seal. -

TCN models (non-automatic)

- Submersible PumpsCast Iron Models

for civil engineering

for civil engineering for industrial equipment

for industrial equipment for pit gray water

for pit gray water

●Built-in automatic return type motor protection device (auto cut).

●The shaft seal uses a double mechanical seal and an oil seal or seal ring (5.5 to 7.5kW only).

●SiC with excellent wear resistance is used for the sliding part of the mechanical seal.

● Built-in equalizer (pressure adjustment mechanism) in the oil chamber (2.2 to 7.5 kW only). -

SD models (non-automatic)

- Submersible PumpsCast Iron Models

for civil engineering

for civil engineering for industrial equipment

for industrial equipment for pit gray water

for pit gray water

● Easy to use and economical, reliable operation even under harsh conditions.

●Simple structure, small size and light weight, and excellent wear resistance.

● We have a wide range of models for general construction that can be used in a wide range of applications.

●Built-in electric motor protector. (11 kW or less) -

SXD models (non-automatic)

- Submersible PumpsCast Iron Models

for civil engineering

for civil engineering for industrial equipment

for industrial equipment for pit gray water

for pit gray water

● All models use aluminum alloy for the motor frame and upper casing.

●The direction of the discharge pipe can be changed so that the hose does not bend or bend unnecessarily.

●Employs a semi-internal motor frame cooling system that enables continuous operation even at low water levels.

●Vortex type impeller with long life and wear resistance.

●Large gap prevents blockage of wood chips and sand, eliminating troubles on site.

●Equipped with an automatic burnout prevention device in the motor. -

SDK models (non-automatic)

- Submersible PumpsCast Iron Models

for civil engineering

for civil engineering for industrial equipment

for industrial equipment

●The main drainage channel is independent, and a very small amount of the drainage is divided to cool the peripheral wall of the motor room, making it compact.

●Strong structure, abrasion resistance, excellent durability.

●Equipped with an automatic burnout prevention device in the motor. (11 kW or less) -

S models (non-automatic; 1.5 to 5.5 kW)

- Submersible PumpsSpecial Synthetic Rubber Models

for civil engineering

for civil engineering for industrial equipment

for industrial equipment

●By using lightweight materials, weight reduction is achieved.

●Vortex type impeller with long life and wear resistance makes it easy to pump water mixed with earth and sand.

● 4-end face SiC mechanical seals are used for shaft seals, and oil immersion method is adopted for outstanding durability.

● Uses a new type motor that keeps the temperature rise of the motor windings low.

●Equipped with an automatic burnout prevention device in the motor. -

TMH models

- Pumps for Specific ApplicationsChemical Models

for the chemical industry

for the chemical industry

TMHM-21N, TMHM-316M (100V, air motor compatible)

●Compact, lightweight and easy to operate.

●Corrosion resistant design.

· TMHM-21N, suitable for transfer solutions of acids and alkalis

· TMHM-316M made of SUS316 for the solvent

●It can also be used for pail cans, plastic cans, and cubitainers (diameter φ31).TMH-55N2 (100V compatible)

●A high lift is achieved by adopting a high-efficiency impeller.

●Weight is reduced by using a compact motor.TMH-108 (100V, air motor, explosion-proof electric motor [100V] compatible)

●The continuous-rated, fully-enclosed fan-cooled motor is covered with integrally molded resin to improve the motor's corrosion resistance and electrical resistance.

●As a motor compatible with explosion-proof environments, we have prepared an explosion-proof motor (d2G3) specification that has passed the type test specified by the Minister of Health, Labor and Welfare.TMH-105 (100V, air motor compatible)

●A high lift (12m) and a large capacity (105ℓ/min) are possible by adopting a high-efficiency impeller.

●Surplus operation due to increased output.

●Even though it uses a large electric motor, the weight is reduced.TMH-107D (SUS) (100V, air motor, explosion-proof electric motor [100V] compatible)

●Corrosion resistant design.

● Made of SUS304, it has excellent chemical resistance. (Designed to be compatible with organic solvents)

●Non-seal structure without liquid leakage. -

TMEX models

- Pumps for Specific Applications

for industrial equipment

for industrial equipment for the chemical industry

for the chemical industry

●Two-stage planetary gear reduction enables long-term continuous operation.

●Special rubber for high pressure resistance and Teflon lining are standard specifications, so it has excellent chemical resistance, and the horizontal repetitive motion of the rod enables the diaphragm to last forever.

●Strengthen the internal mechanism. Stepless adjustment is possible regardless of whether it is running or stopped.

●It is designed so that the intake and discharge valves are completely closed, the discharge rate is stable, and the performance curve is almost straight.

FAQs

Provides help information on how to use each product and when you have problems.